About Us

Central Machine, located in Quakertown Pennsylvania, was founded by Bob Druckenmiller in 1986. Early on a reputation was built that solidified a solid customer base that still stands with the company today. After exceeding capacity, Central Machine expanded into a second location in 2005 that allowed for advancement in facilities and an increase in overall capability. In 2012 the second facility was moved to a new location that holds the possibility for future expansion. Today, Central Machine is a family owned and operated business spanning two generations. Situated in downtown Quakertown; a dozen employees span between two locations totaling 10,000 square feet of manufacturing space.

Central Machine, located in Quakertown Pennsylvania, was founded by Bob Druckenmiller in 1986. Early on a reputation was built that solidified a solid customer base that still stands with the company today. After exceeding capacity, Central Machine expanded into a second location in 2005 that allowed for advancement in facilities and an increase in overall capability. In 2012 the second facility was moved to a new location that holds the possibility for future expansion. Today, Central Machine is a family owned and operated business spanning two generations. Situated in downtown Quakertown; a dozen employees span between two locations totaling 10,000 square feet of manufacturing space.

Central Machine offers a wide range of machining capabilities coming from an impressive depth of employee knowledge and manufacturing experience. From government work for the defense industry to components for the medical and oil & gas industries; Central Machine’s services are utilized by a variety of business sectors. The collection of these industries provides experience with materials including, but not limited to: steels; stainless steels; monel; brass, bronze and their alloys; aluminum; titanium; super alloys such as Inconel® & Hastelloy®; and plastics (Radel®, nylon, Teflon® and PEEK®).

Follow Us on ![]()

@centralmachine

Basic Overview

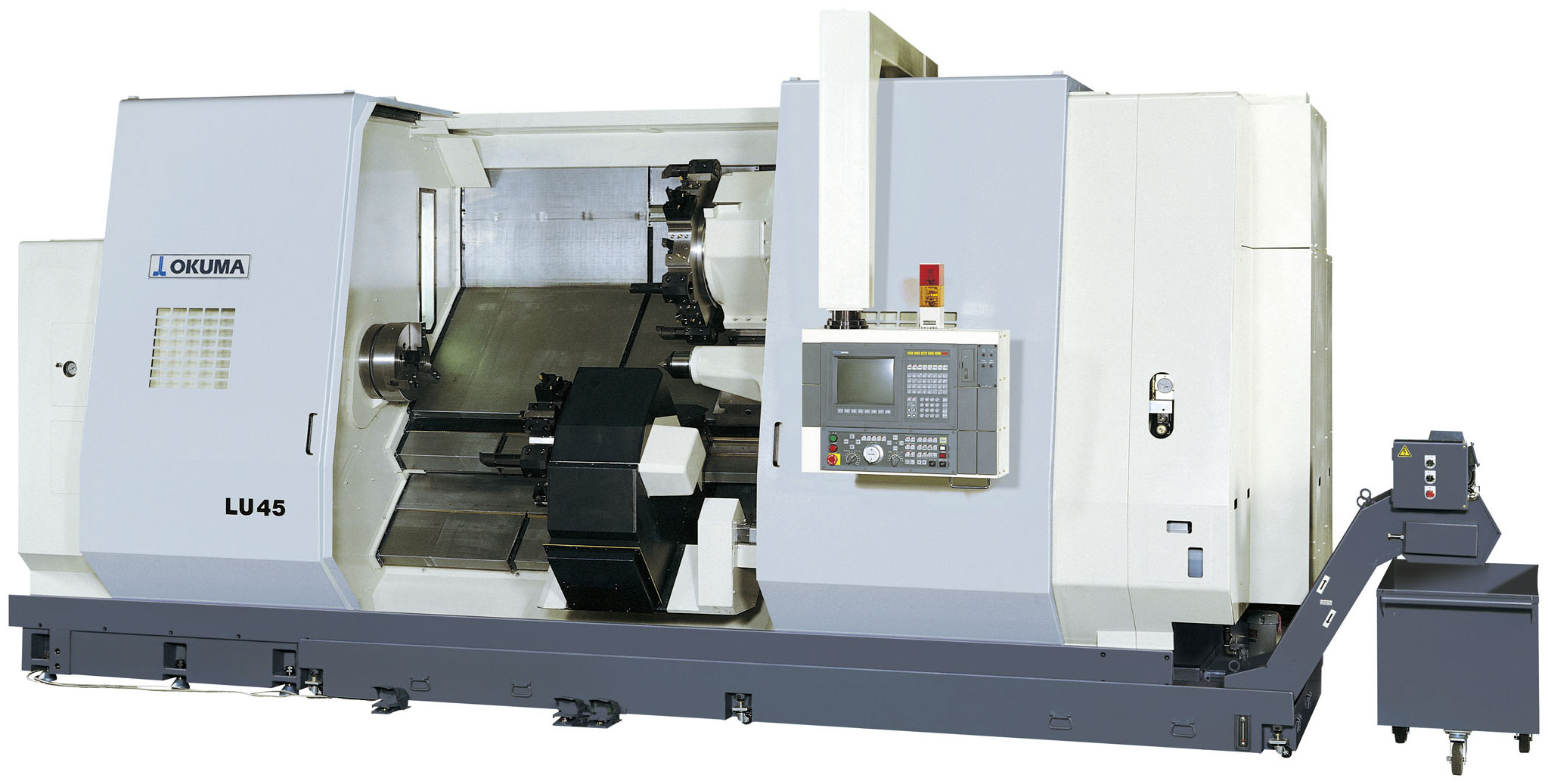

Central Machine exclusively uses Okuma CNC lathes, of which there are 16. Roughly half of these machines are equipped with LNS bar feeders, capable of feeding materials up to 2 5/8 inch diameter. Each machine is equipped with and programmed through Okuma’s proprietary Advanced One-Touch IGF software.

The milling department has two vertical machining centers capable of 4 axis machining. A third Okuma machining center is 5 axis capable. All machines have access to SolidCam software for all of our programming needs.

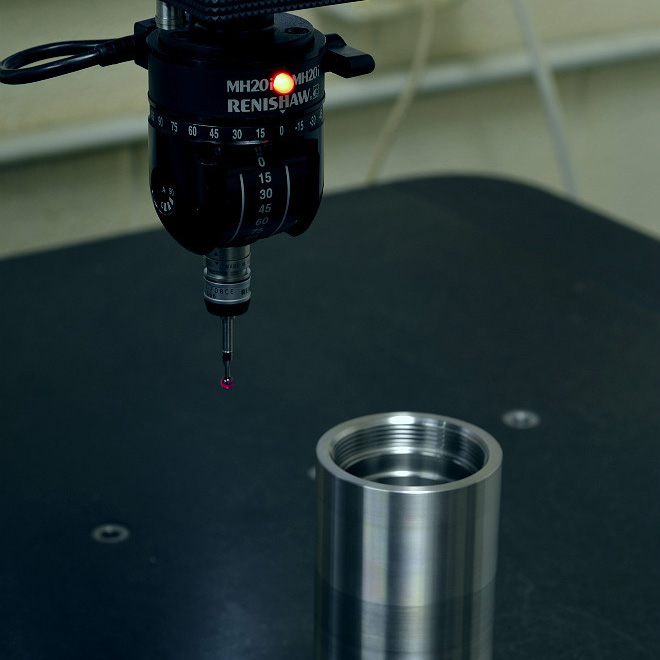

Inspection is furnished with a Mitutoyo coordinate measuring machine and a Deltronic comparator.

Work With Us

Central Machine’s long term relationship with core customers has proven its commitment to consistent quality. Using this first-rate quality and service as a focus, Central Machine continues to build upon new and existing relationships resulting in a hard-earned customer loyalty.

Horizontal Lathes

| Quantity | 1 |

| Barfeeder | LNS Quick Load Servo 80 S2 |

| Turning Diameter | Barfeed: 2 5/8″ Maximum Ø | Chuck: 16.14″ Maximum Ø |

| Extra Features | Live Tooling |

| Sub-Spindle |

| Quantity | 1 |

| Barfeeder | LNS Quick Load Servo 80 S2 |

| Turning Diameter | Barfeed: 2 5/8″ Maximum Ø | Chuck: 11.81″ Maximum Ø |

| Extra Features | Live Tooling |

| Sub-Spindle |

| Quantity | 2 |

| Turning Diameter | 16.14″ Maximum Ø |

| Quantity | 1 |

| Turning Diameter | 7.87″ Maximum Ø |

| Quantity | 2 |

| Turning Diameter | 9.84″ Maximum Ø |

| Quantity | 1 |

| Turning Diameter | 9.84″ Maximum Ø |

| Quantity | 4 |

| Barfeeder | LNS Eco Load |

| Turning Diameter | Barfeed: 1 5/8″ Maximum Ø | Chuck: 8.27″ Maximum Ø |

| Quantity | 2 |

| Barfeeder | LNS Eco Load |

| Turning Diameter | Barfeed: 2″ Maximum Ø | Chuck: 14.17″ Maximum Ø |

| Extra Features | 4 Axis |

| Quantity | 1 |

| Barfeeder | LNS Eco Load |

| Turning Diameter | Barfeed: 2 ½” Maximum Ø | Chuck: 12.20″ Maximum Ø |

| Quantity | 1 |

| Turning Diameter | 7.87″ Maximum Ø |

| Quantity | 1 |

| Turning Diameter | 7.87″ Maximum Ø |